3D Printing

3D printing is an additive manufacturing process where filament is deposited in layers to build physical objects. Following a range of innovations during the late 1990s, engineers began to appreciate the potential of 3D printing to re-invent supply chains and mitigate global challenges.

On this page you’ll learn about 3D printing in five quick sections. Here’s a rundown of what to expect👇🏽

-

We’ll start off with just enough information to help you demystify 3D printing: you’ll get a short introduction to the basics of the 3D printing process and get an idea of what can be done with a 3D printer.

-

Here we’ll define seven buzzwords so that you can start using them in conversation!

-

What can 3D printing actually be used for? In this section we’ll give you some concrete examples to explore. You’ll see that 3D printers can play key roles in overcoming development challenges!

Once you’ve explored some applications of 3D printers, jump into stories from our pilot portfolio, where they’re testing 3d printing in the field.

-

Evidence is at the heart of the Frontier Tech Hub, and we’ve collated insights from our portfolio and thought leadership from FCDO Pioneers in this section. Dig into our research to look deeper at how 3D printers can be used within FCDO programmes.

-

More resources, however you like to consume. We’ve created a playlist of podcasts, reports, articles and videos to continue your journey. There’s something for everyone.

How to 3D print

How to 3D print in three easy steps:

CAD modelling: The process of 3D printing starts with a 3D CAD (computer aided design) model. Using CAD software a maker can design a virtual model of an object, which can represent any property that a physical object could potentially have: shape, size, material, mass, strength etc. Once designed these models can be tested on the software to determine how the object will function in different circumstances.

Slicing: 3D printers work by printing detailed layers on top of each other which combine to form a physical object. The CAD models described above represent the specifications for the object as a whole. For the 3D printer to be able to “understand” the model, it needs to be broken down into layers. This is where the process of slicing comes in. Slicing software takes the CAD model and breaks it down into a set of layers. This data can then be fed into the 3D printer to start the manufacturing process.

Printing: A helpful way to consider the printing process is to imagine a 3 dimensional grid with an X, Y and Z axis. In a traditional printer, the extruder (imagine a robotic arm) moves across the X-axis depositing ink, while the paper is pushed perpendicular to it along the Y-axis. With 3D printing, the extruder moves around the X and Y axis, depositing hot filament through a nozzle, which is cooled using a fan until it solidifies. Filament is deposited according to the coordinates coded in the slicing file. Once the layer is completed, the extruder moves up the Z axis to repeat the process, adding subsequent layers until a 3D object is created.

(This describes the process for FDM printing, see below to understand how different types of 3D printers work).

What if we could print…

🏥Vaccines: Engineers at MIT have been testing the possibility of printing a single shot, containing a biodegradable cup, which releases multiple vaccines at predetermined rates. Children who cannot easily reach hospitals, would be able to receive all of their vaccines at once, greatly improving their access to lifesaving healthcare.

🥞Food: Using a similar method to FDM printers, food stuffs can be deposited in layers to build complex food items, ranging from intricate cakes to synthetic meat developed from animal cells.

🏠Houses: in 2020 SQ4D built the largest 3D printed house in the world. The 600m house has three bedrooms, a bathroom and was created in 48 hours, using just $6000 of materials.

🚀A habitat on the moon: NASA are exploring the potential of using autonomous 3D printers to construct a lunar base. This could reduce a future settlement's reliance on Earth’s supplies and build a sustainable manufacturing system in space.

🥼Organs: Engineers have begun testing whether 3D printers could be used to print functioning organs using a patient's own cells. This could reduce the demand for transplants from donors and the chance of organs being rejected.

If you’re completely new to 3D printing, we would recommend taking these three quick steps first:

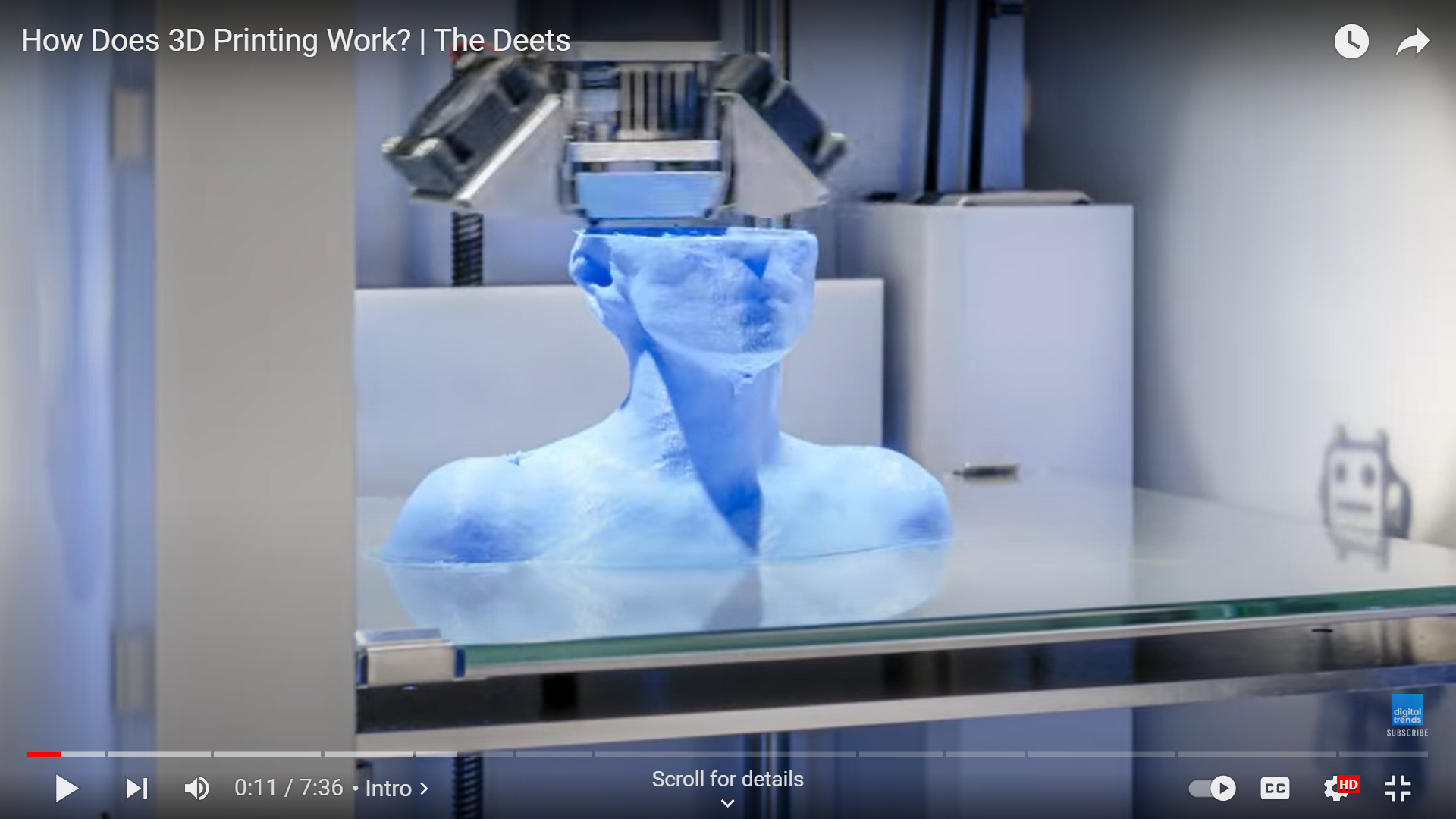

Watch this seven-minute video to understand the different kinds of 3D printer and some key use-cases

Learn how 3D printing is changing the manufacturing industry in this short read

Explore the thingyverse, and get a sense of what people are producing using 3D printers

Master 7 key buzzwords

If you want to learn more about distributed manufacturing check out these resources:

Distributed manufacturing, a key use-case of 3D printers, is an organisational system where resources are produced nearer to end-users than traditional, centralised manufacturing systems. Instead of mass producing common designs and distributing them through supply chains, producers in a distributed system can determine the needs of their local context, and create products that suit that context. Consider a hospital, which has its own 3D printer producing spare parts to fix broken machinery, instead of relying on supply chains connected to centralised factories. The reasonably low-cost of entry, potential for customisation and flexibility of the 3D printing process, facilitate this kind of system.

Functionality

What is possible using 3D printers?

Explore stories from the pilot portfolio, testing 3D printers in the field

Insights from the Hub

Resources we’ve created from insights gathered across the Hub - more on 3D printing coming soon!

Fab Lab Nepal — In the foothills of the Digital Himalayas

An introduction to the Fab Lab concept

(1/3) How to Test if Your Organisation is Ready for Distributed Manufacturing?

A step-wise guide to design experiments to explore the feasibility of aligning a distributed manufacturing system with procurement processes in organisations

Pilot Story: Manufacturing for the next frontier in Kenya

A story of implementing 3D printers to improve local supply chains

Distributed Manufacturing: Building Resilience through Local Manufacturers in a Post-COVID South Asia

Explore how BRAC are leveraging local makerspaces to make their responses on the ground more resilient